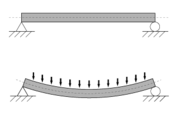

Structural failure refers to loss of the load-carrying capacity of a component or member within a structure or of the structure itself. Structural failure is initiated when the material is stressed to its strength limit, thus causing fracture or excessive deformations. The ultimate failure strength of the material, component or system is its maximum load-bearing capacity. When this limit is reached, damage to the material has been done, and its load-bearing capacity is reduced permanently, significantly and quickly. In a well-designed system, a localized failure should not cause immediate or even progressive collapse of the entire structure. Ultimate failure strength is one of the limit states that must be accounted for in structural engineering and structural design.

|

Contents

- 1 Dee bridge disaster

- 2 First Tay Rail Bridge

- 3 First Tacoma Narrows Bridge

- 4 de Havilland Comet

- 5 Ronan Point

- 6 Hyatt Regency walkway

- 7 Oklahoma City bombing

- 8 9/11

- 9 I-35W Bridge Collapse

- 10 See also

- 11 References

- 12 External links

|

Dee bridge disaster

The Dee bridge after its collapse

Main article: Dee bridge disaster

On 24 May, 1847 the Dee Bridge collapsed as a train

passed over it, with the loss of 5 lives. It was designed by Robert Stephenson, using cast iron girders reinforced with wrought iron struts. The bridge collapse was the subject of one of the first formal inquiries into

a structural failure. The result of the inquiry was that the design of the structure was fundamentally flawed, as the wrought iron did not reinforce the cast iron at all, and due to repeated flexing it

suffered a brittle failure due to fatigue.[1]

First Tay Rail Bridge

Main article: Tay Bridge disaster

The Dee bridge disaster was followed by a number of cast iron bridge collapses, including the collapse of the first Tay Rail

Bridge on 28 December 1879. Like the Dee bridge, the Tay collapsed when a train passed over it causing 75 people to lose their lives. The bridge failed because of poorly made cast iron,

and the failure of the designer Thomas Bouch to consider wind loading on the bridge. The collapse resulted in cast iron largely being

replaced by steel construction, and a complete redesign in 1890 of the Forth Railway Bridge. As a result, the Forth Bridge

was the first entirely steel bridge in the world.[2]

First Tacoma Narrows Bridge

Tacoma Narrows Bridge collapsing

Main article: Tacoma Narrows Bridge (1940)

The 1940 collapse of Tacoma Narrows Bridge, as the original Tacoma Narrows Bridge is known, is

sometimes characterized in physics textbooks as a classical example of resonance; although, this description is misleading. The catastrophic vibrations that destroyed the bridge were not due to

simple mechanical resonance, but to a more complicated oscillation between the bridge and winds passing through it, known as aeroelastic flutter. Robert H. Scanlan, father of the field of bridge aerodynamics, wrote an article about

this misunderstanding[3]. This collapse, and the research that followed, led to an

increased understanding of wind/structure interactions. Several bridges were altered following the collapse to prevent a similar event occurring again. The only fatality was ‘Tubby’ the dog.[2]

de Havilland Comet

Main articles: BOAC Flight 781 and South African Airways Flight 201

In 1954, two de Havilland Comet C1 airliners, the world’s first commercial jet airliner, crashed, killing all passengers. After

lengthy investigations and the grounding of all Comet airliners, it was concluded that metal fatigue at the corners of

the windows had resulted in the crashes. The square corners had led to stress concentrations which after continual stress

cycles from pressurisation and de-pressurisation, failed catastropically in flight. The research into the failures led to significant improvements in understanding of fatigue loading of airframes, and

the redesign of the Comet and all subsequent airliners to incorporate rounded corners to doors and windows.

Ronan Point

Main article: Ronan Point

On 16 May, 1968 the 22 storey residential tower Ronan Point in the London borough of Newham collapsed when a relatively small gas explosion on the 18th floor caused a structural wall panel to be blown away from the building. The tower was constructed

of precast concrete, and the failure of the single panel caused one entire corner of the building to collapse. The panel was able to

be blown out because there was insufficient reinforcement steel passing between the panels. This also meant that the loads carried by the panel could not be redistributed to other adjacent panels,

because there was no route for the forces to follow. As a result of the collapse, building regulations were overhauled to prevent “disproportionate collapse”,[clarification needed] and the understanding of precast concrete detailing was greatly advanced. Many similar buildings were altered or demolished as a result of the

collapse.[4]

Hyatt Regency walkway

Design change on the Hyatt Regency walkways.

Main article: Hyatt Regency walkway

collapse

On 17 July, 1981, two suspended walkways through the lobby of the Hyatt Regency in Kansas City, Missouri, collapsed, killing 114 people at a tea dance. The collapse was due to a late change in design, altering

the method in which the rods supporting the walkways were connected to them, and inadvertently doubling the forces on the connection. The failure highlighted the need for good communication

between design engineers and contractors, and rigorous checks on designs and especially on contractor proposed design changes. The failure is a standard case study on engineering courses

around the world, and is used to teach the importance of ethics in engineering.[5][6]

Oklahoma City bombing

Main article: Oklahoma City bombing

On 19 April, 1995, the nine story concrete framed Alfred P. Murrah Federal Building in Oklahoma was struck by a huge car bomb causing partial collapse, resulting in the deaths of 168 people. The bomb, though large, caused a

significantly disproportionate collapse of the structure. The bomb blew all the glass off the front of the building and completely shattered a ground floor reinforced concrete column (see brisance). At second story level a wider column spacing existed, and loads from upper story columns were transferred into fewer columns below by

girders at second floor level. The removal of one of the lower story columns caused neighbouring columns to fail due to the extra load, eventually leading to the complete collapse of the central

portion of the building. The bombing was one of the first to highlight the extreme forces that blast loading from terrorism can exert on buildings, and led to increased consideration of terrorism in

structural design of buildings.[7]

9/11

Main article: Collapse of the World Trade

Center

In the September 11 attacks, two commercial airliners were deliberately crashed into the Twin Towers of the World Trade Center in New York City. The impact and resulting fires caused both towers to collapse within two hours. After the

impacts had severed exterior columns and damaged core columns, the loads on these columns were redistributed. The hat trusses at the top of each building played a significant role in this

redistribution of the loads in the structure.[8] The impacts dislodged

some of the fireproofing from the steel, increasing its exposure to the heat of the fires. Temperatures became high enough to weaken the core columns to the point of creep and plastic deformation under

the weight of higher floors. Perimeter columns and floors were also weakened by the heat of the fires, causing the floors to sag and exerting an inward force on exterior walls of the building.[9][10]

I-35W Bridge Collapse

Main article: I-35W Mississippi River bridge

The I-35W Mississippi River bridge (officially known simply as Bridge 9340) was an eight-lane steel truss arch bridge that

carried Interstate 35W across the Mississippi

River in Minneapolis, Minnesota,

United States. The bridge was completed in 1967, and its maintenance was performed by the Minnesota Department of Transportation. The bridge was Minnesota’s fifth–busiest,[11][12] carrying 140,000 vehicles daily.[13] The bridge catastrophically failed

during the evening rush hour on August 1, 2007, collapsing to the river and riverbanks beneath. Thirteen people were killed and 145 were injured.

Following the collapse The Federal Highway Administration (FHWA)advised states to inspect the

700 U.S. bridges of similar construction[14] after a possible design flaw in the bridge

was discovered, related to large steel sheets called gusset plates which were used to connect girders together

in the truss structure.[15][16] Officials expressed concern about many other bridges in the United States sharing the same

design and raised questions as to why such a flaw would not have been discovered in over 40 years of inspections.[16]

See also

- List of structural failures and collapses

- Catastrophic failure

- Earthquake engineering

- List of bridge disasters

- Porch collapse

- Forensic engineering

- Progressive collapse

- Seismic performance

- Collapse zone